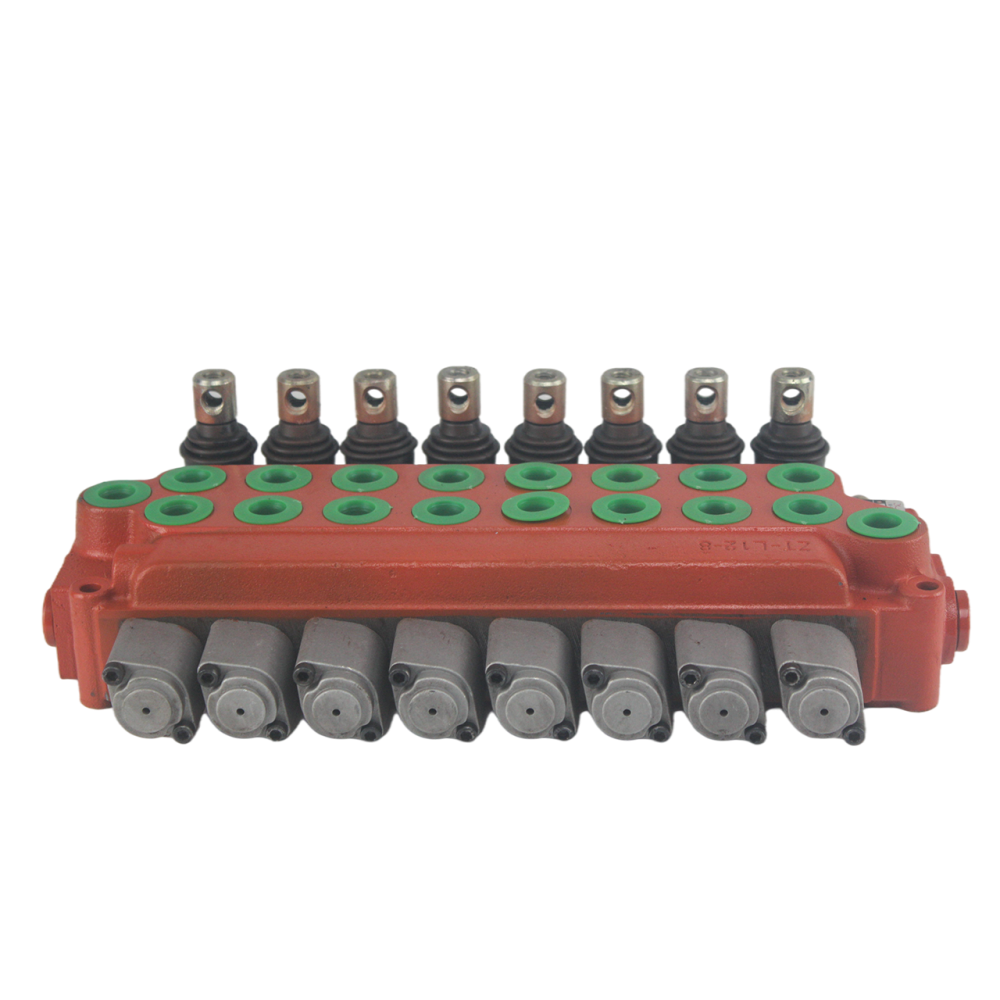

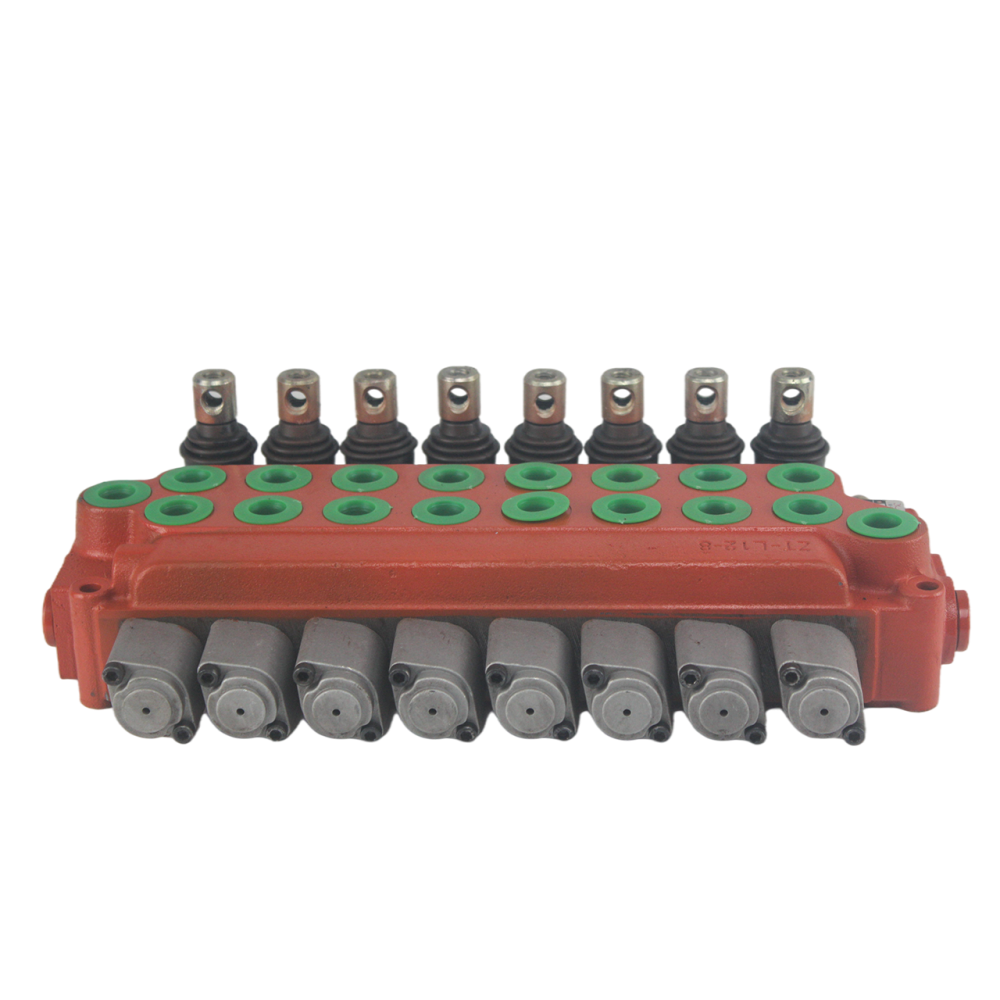

There are many types of hydraulic monoblock valves according to their structure, including conversion valves, Throttle Valves, unloading valves, check valves, etc. Among them, the conversion valve is the most widely used type, which can combine multiple hydraulic circuits to achieve various hydraulic control functions. The throttle valve is used to limit flow and regulate pressure; The unloading valve is used to remove pressure from the system and protect the safety of the hydraulic system; Check valves are used to prevent reverse fluid flow and effectively protect equipment.

In practical use, monoblock hydraulic directional valves also need to be selected according to different working conditions. For example, under high temperature or high pressure working conditions, it is necessary to choose high-temperature and high-pressure resistant multi-way valves; When used in special media, corrosion-resistant materials need to be selected; When used in high-speed equipment, it is necessary to choose high sensitivity multiple valves, etc.

In short, as an important hydraulic control component, the role of a monoblock Hydraulic Control Valve cannot be ignored. In different work scenarios, different types and specifications of monoblock valves need to be selected to meet different hydraulic system control requirements.

We Huai'an Vanke Hydraulic Machinery Co., Ltd have hydraulic control valve, Directional Valve, Monoblock Valve, Sectional Valve, proportional valve, Solenoid Valves and so on. Our Hydraulic Valve are subdivided into three main categories: Directional Control Valves, pressure control valve and flow control valves. All valves operate a different function in the hydraulic system. Hydraulic monoblock directional control valve includes handle / manual control, electric control, hydraulic control, electric-hydraulic control, pneumatic control, electric-pneumatic control and so on.