Manual Valve is a type of valve that is operated manually by turning a handle or lever to open or close the valve. Manual valves are commonly used in applications where the flow of fluids or gases needs to be controlled manually, such as in plumbing systems, heating and cooling systems, and industrial processes. The type of manual valve used depends on the specific application and the requirements of the system.

These valves have different positions or states, such as open or closed, which determine the direction of fluid flow. They can be used to control the movement of hydraulic cylinders, motors, or other hydraulic components.

The main advantage of manual operated Directional Control Valves is their simplicity and reliability. They do not require any external power source and can be operated even in remote locations or in the event of power failure.

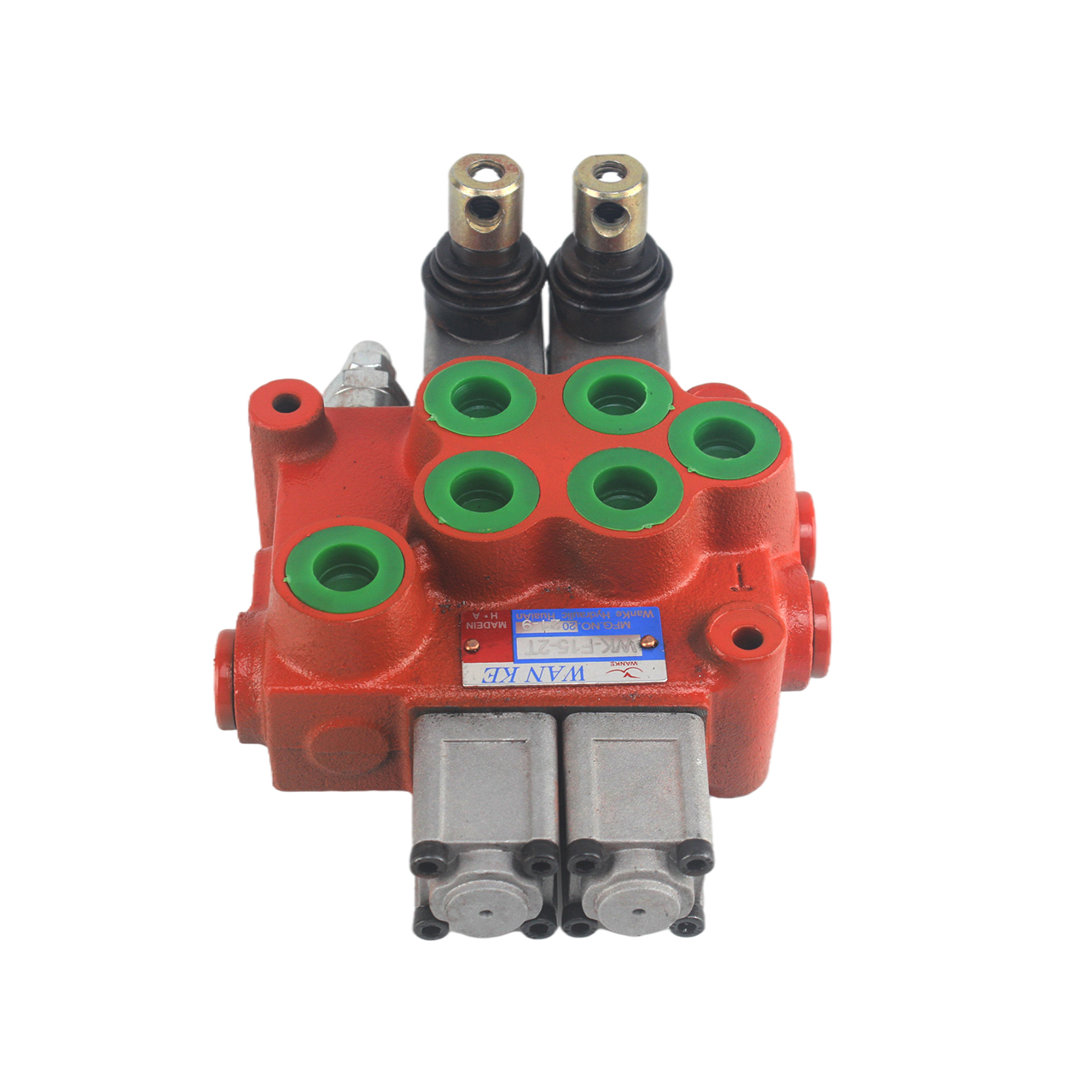

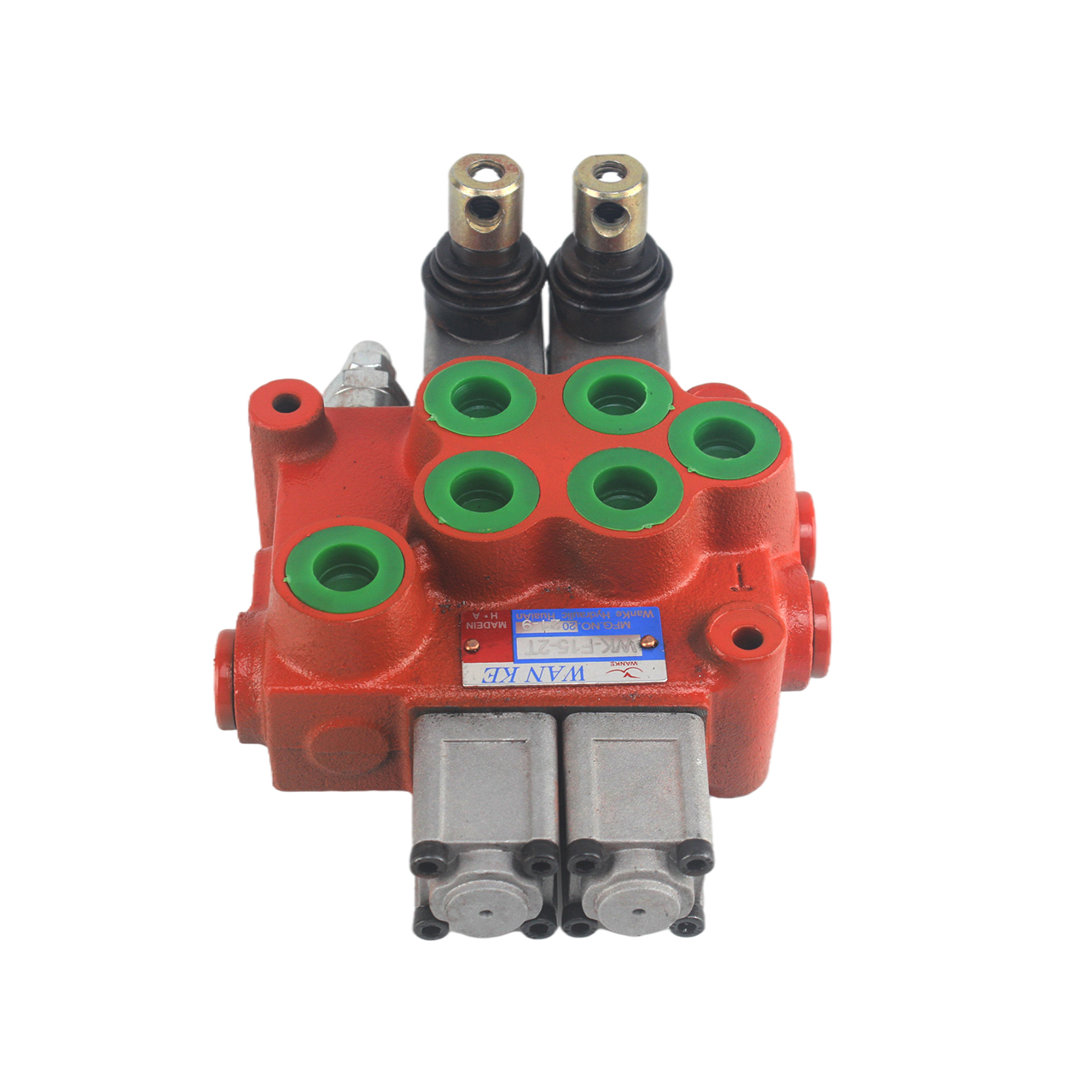

Hydraulic manual operated directional control valves is can be widely used in hydraulic systems of construction machinery, forklift truck, environment sanitation vichicles, farm agriculture tractor, transportation machine, crane equipment, mining machinery and so on.

It is important to follow the manufacturer's instructions and guidelines when installing and operating hydraulic manual operated directional control valves to ensure safe and efficient operation of the hydraulic system.

Our Hydraulic Valve are subdivided into three main categories: directional control valves, pressure control valve and flow control valves. All valves operate a different function in the hydraulic system. Hydraulic monoblock directional control valve includes handle / manual control, electric control, hydraulic control, electric-hydraulic control, pneumatic control, electric-pneumatic control and so on. Our Hydraulic Valve (Hydraulic Control Valve, Directional Valve, Monoblock Valve, Sectional Valve, proportional valve, Solenoid Valves and so on) properly directs the flow of hydraulic oil through your hydraulic system. The direction of the oil flow is determined by the position of a spool. The required size is determined by the maximum flow of the hydraulic system through the valve and the maximum system pressure. You can use direction valves to switch at a certain pressure or adjust the direction and flow of the fluid.