Directional hydraulic spool control valve is a device used to control the flow of hydraulic fluid in a hydraulic system. It consists of a spool that can be moved back and forth to direct the flow of fluid to different hydraulic actuators.

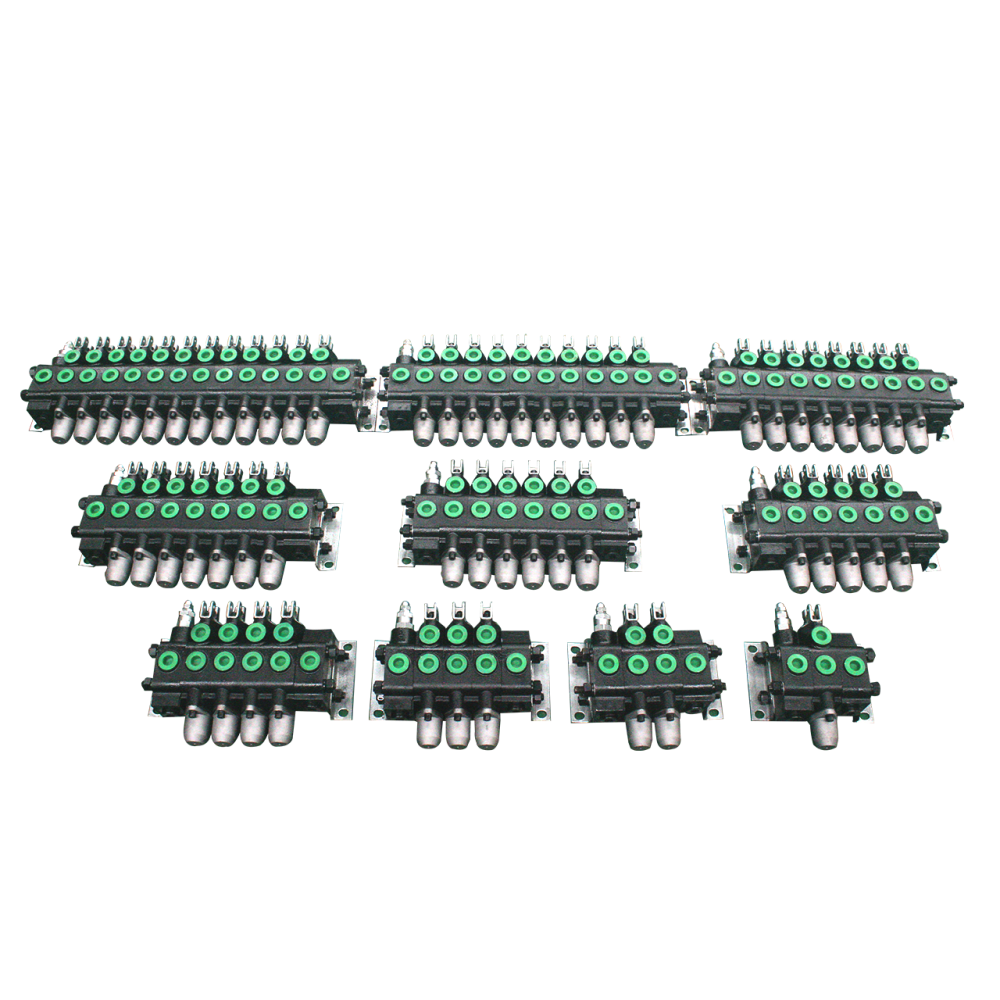

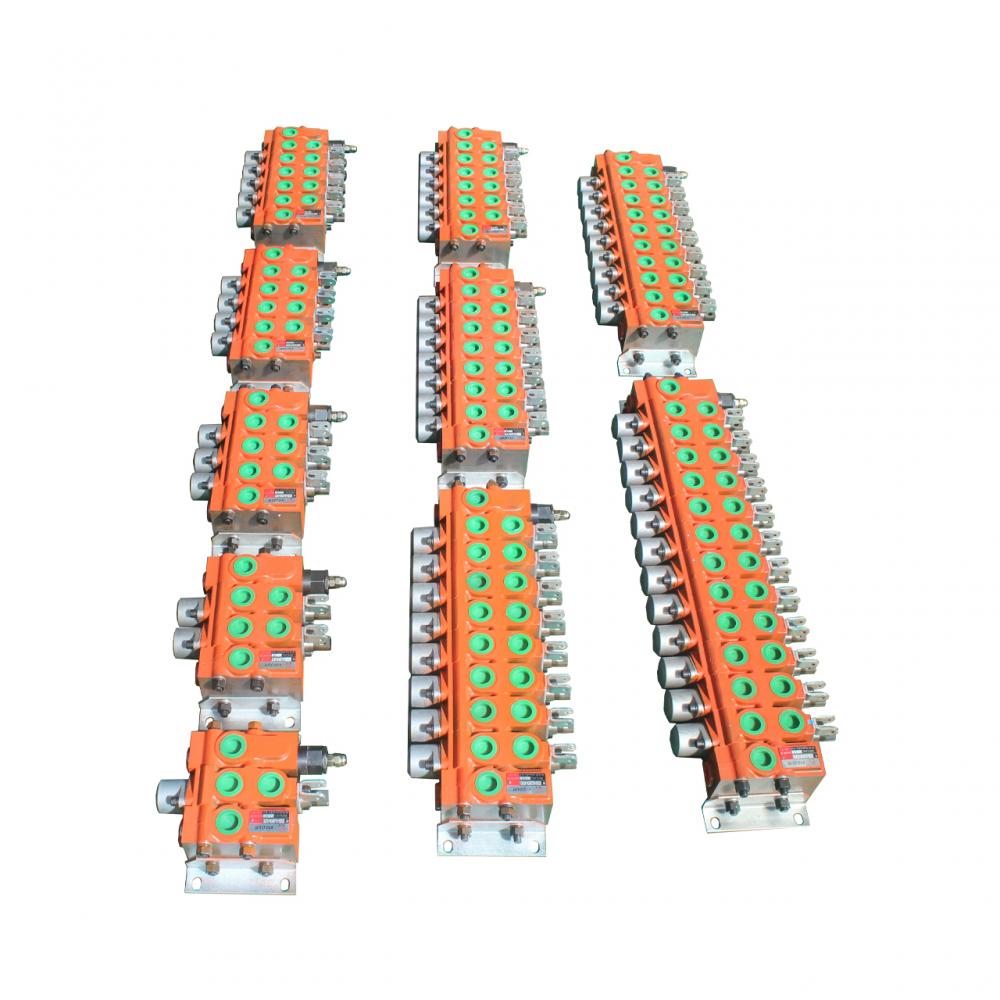

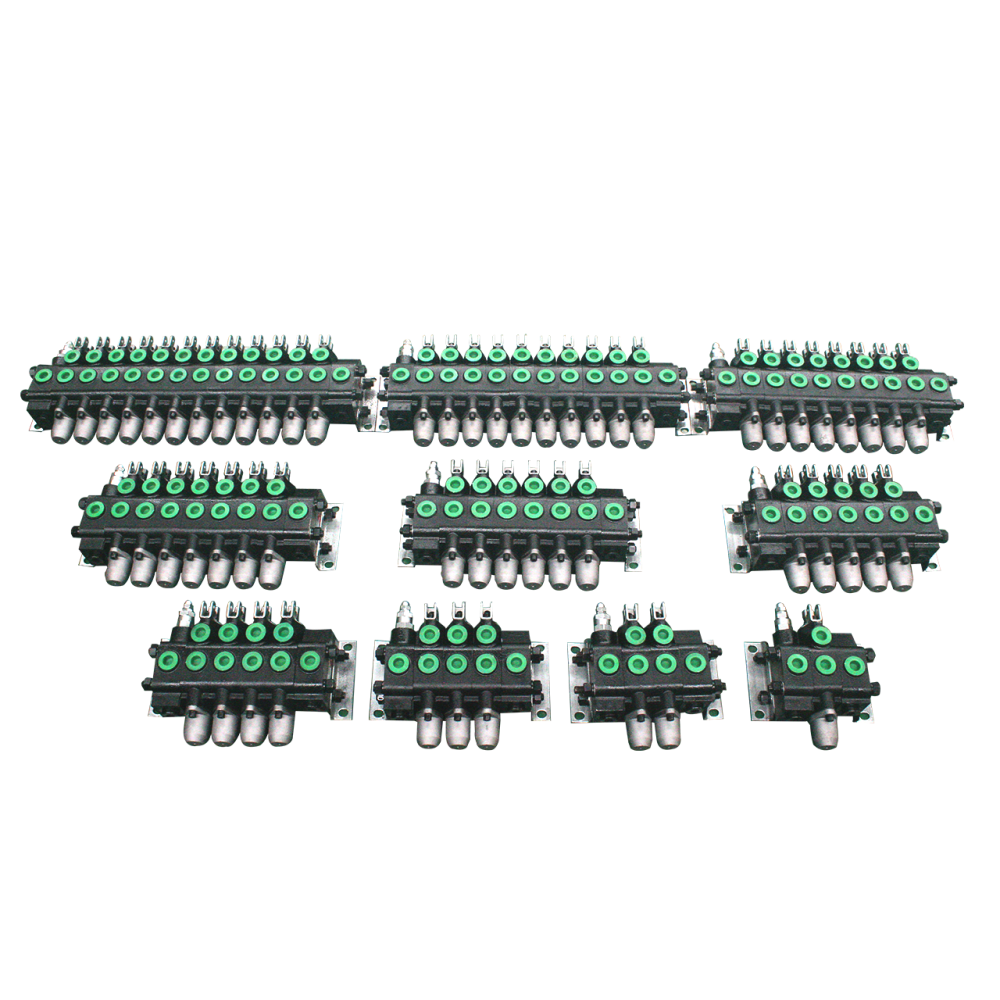

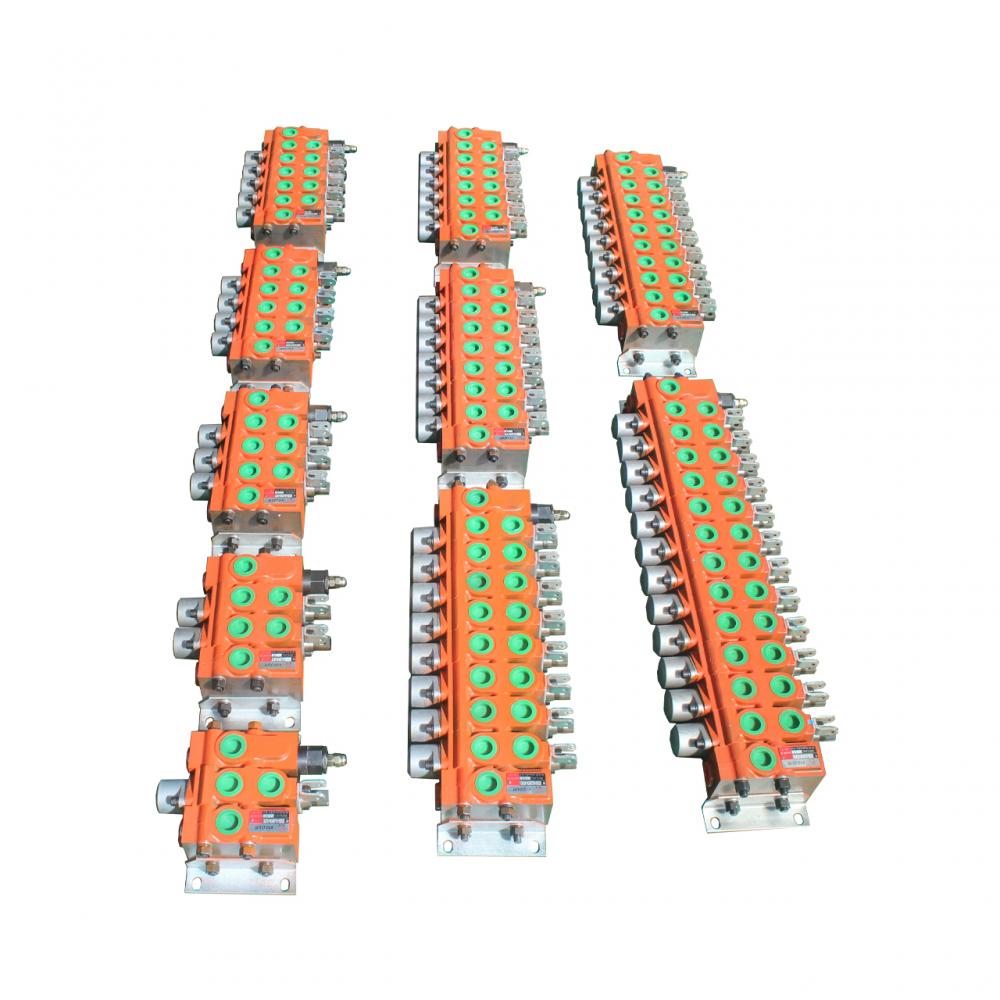

The monoblock spool Hydraulic Control Valve typically has multiple ports for connecting hydraulic lines, including an inlet port, outlet ports, and work ports. The inlet port is connected to the hydraulic pump, which supplies pressurized fluid to the valve. The outlet ports are connected to the hydraulic actuators, such as cylinders or motors, which use the fluid to generate mechanical force or motion. The work ports are used to redirect the fluid flow to different actuators.

The spool inside the valve has various positions or "lands" that correspond to different flow paths. By moving the spool, the operator can select which flow path is active. For example, moving the spool to one position may direct the fluid to actuate a cylinder in one direction, while moving it to another position may reverse the flow to actuate the cylinder in the opposite direction.

Hydraulic directional control monoblock valve is commonly used in various applications, including construction equipment, agricultural machinery, and industrial machinery. They are essential for controlling the movement of hydraulic cylinders, motors, and other hydraulic actuators in these systems.

We Huai'an Wanke Hydraulic Machinery Co., Ltd have hydraulic control valve, Directional Valve, Monoblock Valve, Section Valve, proportional valve, Solenoid Valves and so on. Our Hydraulic Valve are subdivided into three main categories: Directional Control Valves, pressire control valve and flow control valves. All valves operate a different function in the hydraulic system. Hydraulic monoblock directional control valve includes handle / manual control, electric control, hydraulic control, electric-hydraulic control, pneumatic control, electric-pneumatic control and so on.