Generally, our Hydraulic Valve are subdivided into three main categories: Directional Control Valves, pressure control valve and flow control valves. All valves operate a different function in the hydraulic system. We Vanke factory have Hydraulic Control Valve, Directional Valve, Monoblock Valve, Sectional Valve, proportional valve, Solenoid Valves and so on. Hydraulic monoblock directional control valve includes handle / manual control, electric control, hydraulic control, electric-hydraulic control, pneumatic control, electric-pneumatic control and so on.

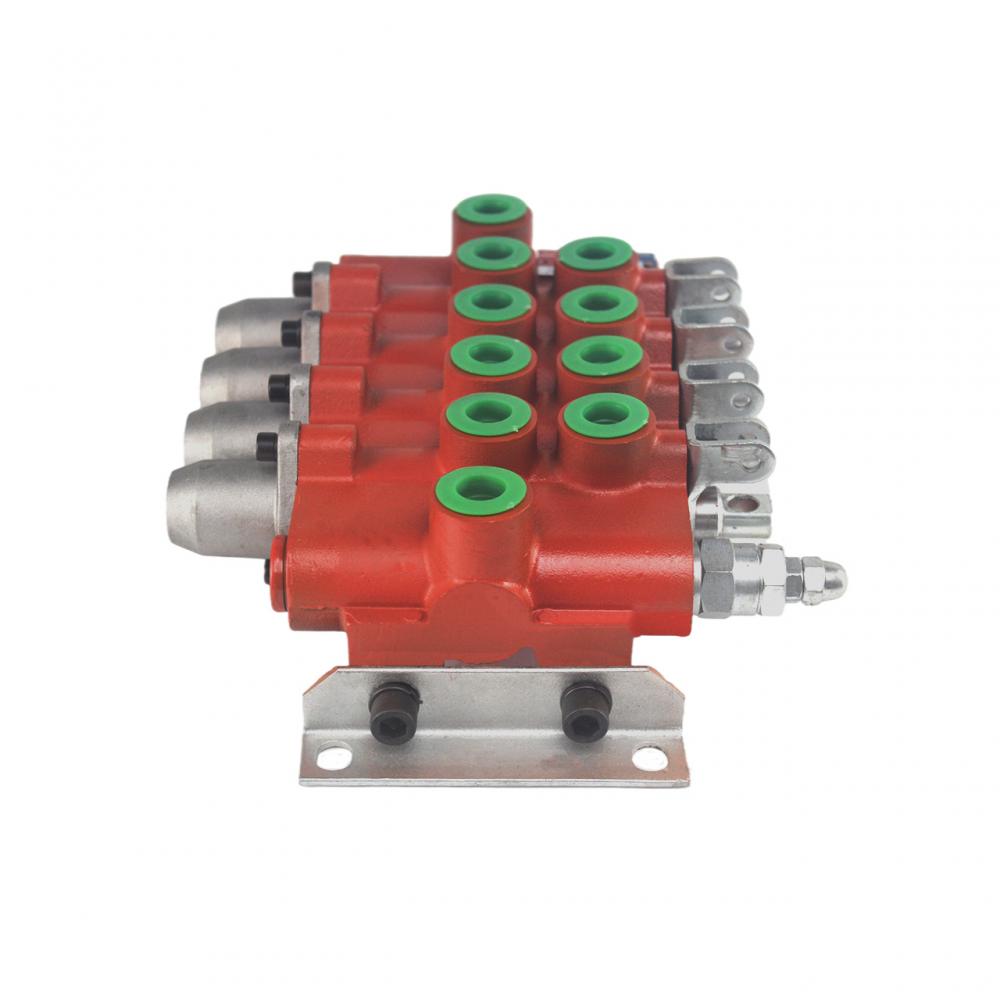

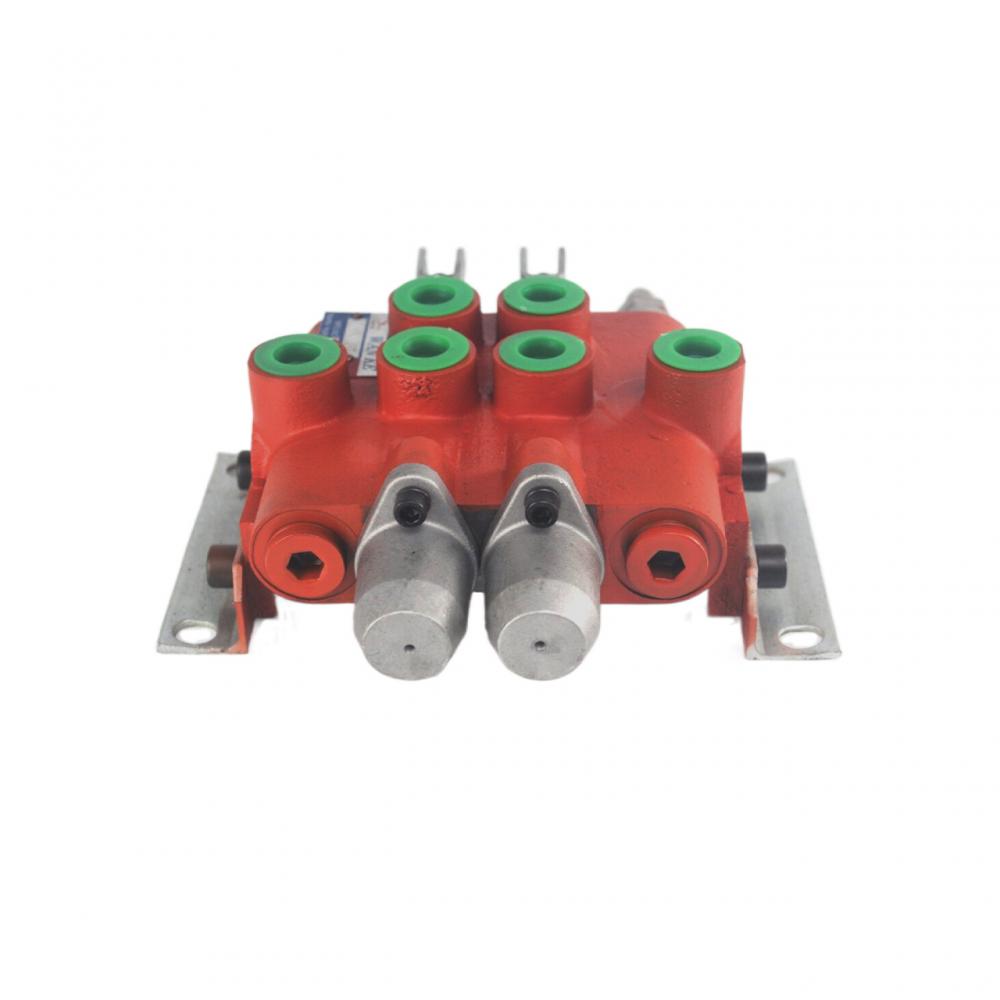

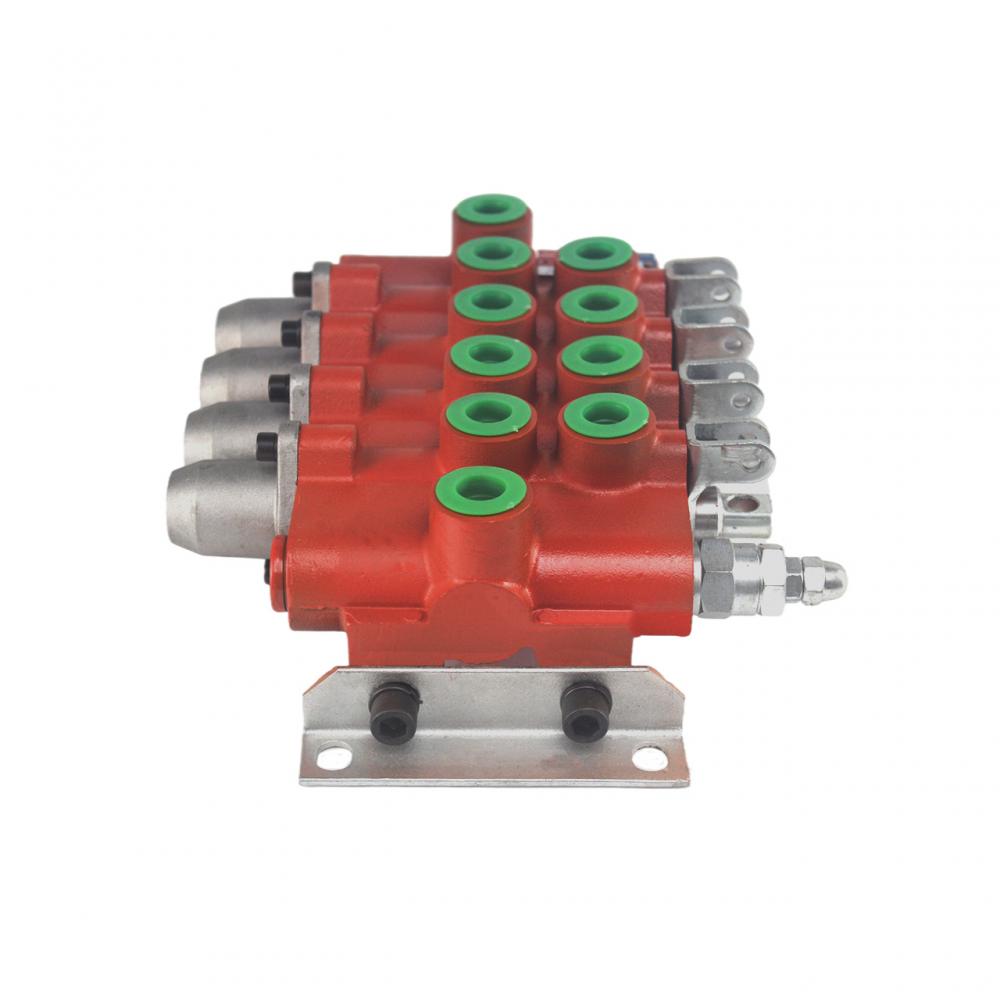

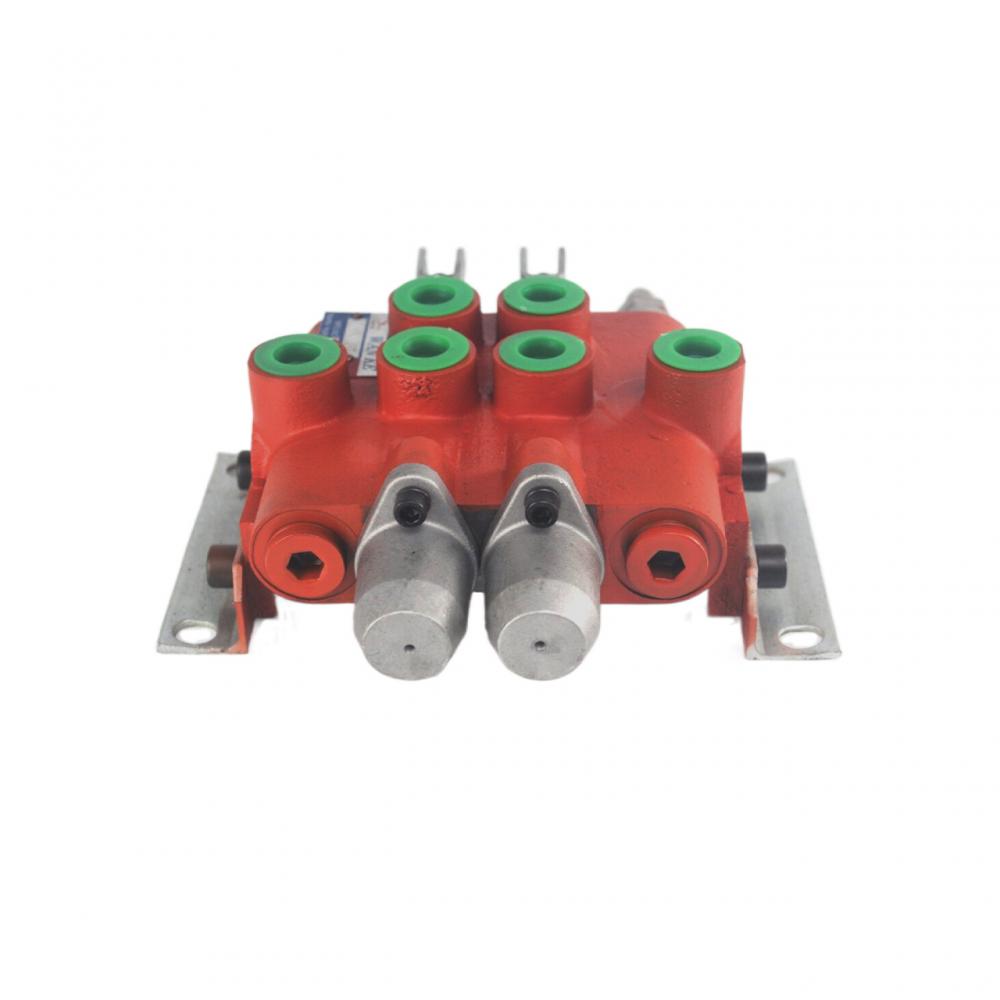

Control valve hydraulic monoblock directional valve 1 spool is medium-high pressure integrity way monoblock directional valve independently designed and developed by our factory. To prevent oil leakage between chips, it has the characteristics of high pressure and anti Overflow Valve blockage. The functions of the directional valve spool valve include A, O, Y, etc. The specially designed sealing method ensures excellent sealing performance of the valve. It has spring return, ball locking positioning returning ways. The valve is widely used in the hydraulic system of forklift, sanitation vehicle and light Loading machines.

Directional hydraulic control valve is a type of valve that controls the direction of the flow of fluid in a hydraulic system. It is commonly used in hydraulic machinery and equipment to control the movement of cylinders, motors, and other hydraulic components. The valve has multiple ports, which can be connected to different hydraulic lines to control the flow of fluid. The monoblock valve can be actuated manually, electrically, or by other means to change the direction of fluid flow. There are different types of directional control valves, including spool valves, poppet valves, and rotary valves. Each type has its own advantages and disadvantages, and the choice of valve depends on the specific application and requirements of the hydraulic system.